Raise Results with Our Materials Test Lab Expertise

Wiki Article

Putting Products to the Examination: Discovering the Role of Materials Test Labs

Materials test labs play a crucial role in guaranteeing the top quality and reliability of various materials used in markets such as aerospace, building and construction, and production. These labs perform strenuous testing to assess the performance, strength, toughness, and safety and security of products, allowing firms to make enlightened choices regarding their use in frameworks and products. Via a mix of sophisticated techniques and specialized tools, products test labs are able to assess the buildings of steels, polymers, composites, and various other products under different problems and stressors. The outcomes acquired from these tests provide beneficial insights into product actions, permitting developers and designers to optimize their items and processes. This write-up will explore the relevance of products testing, the kinds of materials examined, testing strategies and devices used, along with the applications of materials examination results. Additionally, it will certainly discuss future fads in materials screening, highlighting the continual improvements in this field.Value of Products Testing

Frequently evaluating the quality of products is important in ensuring the integrity and safety and security of products in various sectors. Materials testing entails subjecting materials to numerous examinations and experiments to examine their mechanical, physical, and chemical residential properties.One of the key factors why materials screening is very important is the guarantee of item top quality. With strenuous screening, producers can recognize any defects or weak points in the products made use of for their items. This allows them to make needed improvements to boost the overall top quality and performance of their items. Materials screening assists in recognizing prospective concerns that may develop during the product's lifecycle, such as wear and tear, deterioration, or architectural failures. By attending to these problems at an early stage, suppliers can avoid pricey recalls, lawsuits, and reputational damage.

By subjecting products to different tests, manufacturers can establish their resilience, resistance, and strength to outside factors such as warmth, pressure, or chemicals. Whether it is automotive elements, medical tools, or building materials, products testing assists in identifying any kind of possible safety and security risks and creating suitable measures to alleviate them.

Types of Products Tested

Various kinds of materials are checked in materials test laboratories to assess their mechanical, physical, and chemical homes. These products can incorporate a vast array important, consisting of steels, polymers, ceramics, composites, and also all-natural materials such as timber and concrete.Steels are generally tested due to their prevalent usage in different markets. Composites, which consist of 2 or even more various products, are assessed to comprehend their total efficiency, consisting of aspects like durability, versatility, and toughness.

All-natural materials like wood are tested to evaluate their toughness, dampness material, and resistance to degeneration (materials test lab). Concrete is one more typically tested product, with tests concentrating on its compressive toughness, resilience, and resistance to ecological aspects

In addition to these products, materials test labs also review finishes, paints, adhesives, and various other products used in construction, production, and various other industries. By subjecting these products to rigorous screening, engineers and scientists can collect beneficial data to educate material choice, design optimization, and high quality control procedures.

Checking Strategies and Equipment

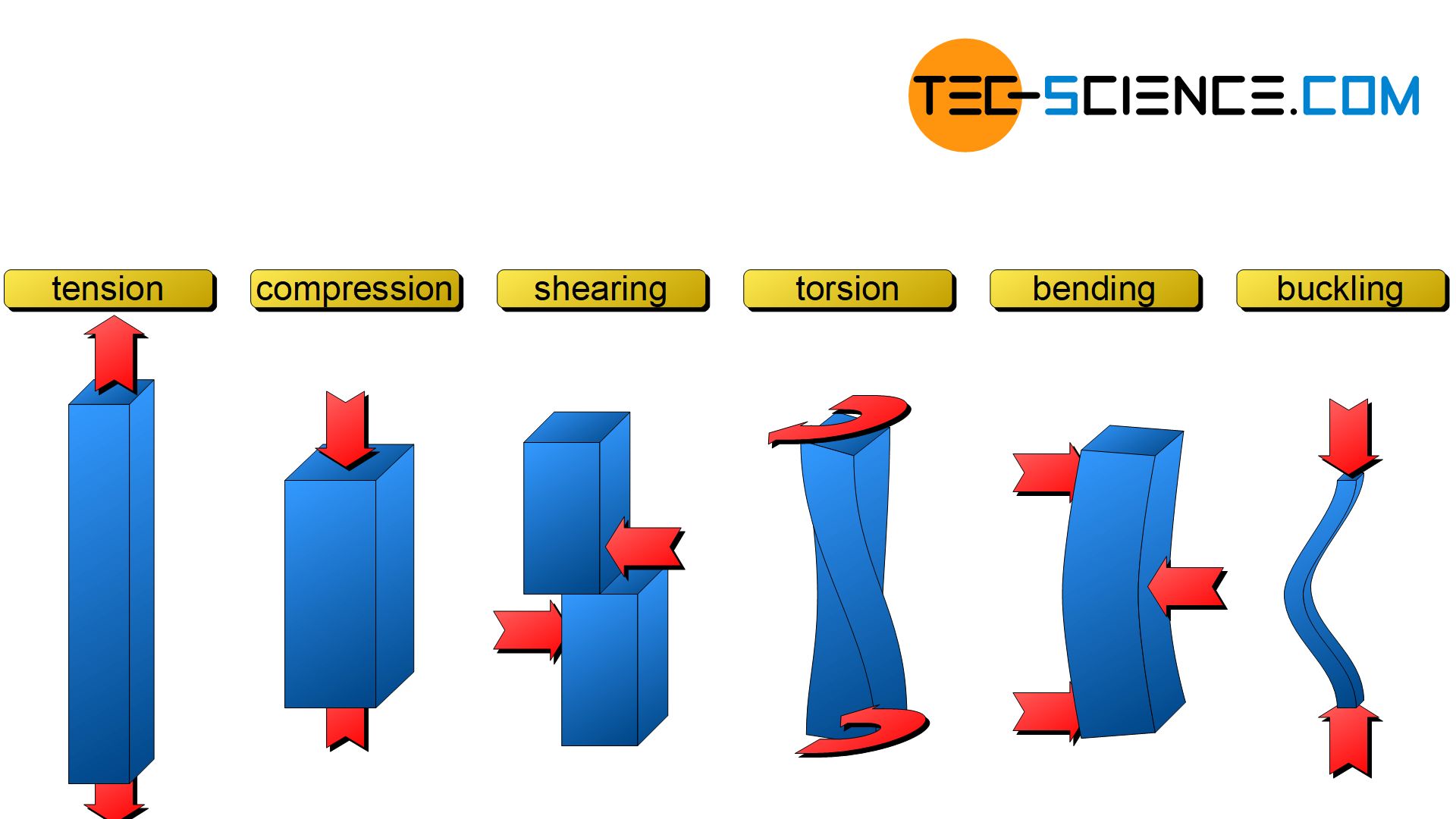

Evaluating strategies and equipment play a critical role in materials examination laboratories for evaluating the mechanical, physical, and chemical residential or commercial properties of numerous products. These techniques and devices are crucial in ensuring the high quality, integrity, and safety and security of products utilized in different sectors such as aerospace, automotive, construction, and medical.One frequently made use of testing method in products examination laboratories is mechanical screening, which entails subjecting products to various forces or lots to determine their strength, hardness, ductility, and other mechanical residential properties. This is usually done using equipment such as universal testing equipments, which can use tensile, compressive, and flexing pressures to examine samplings.

Physical screening strategies are likewise utilized to assess homes such as density, viscosity, thermal conductivity, and electrical conductivity. Equipment such as thickness meters, viscometers, thermal conductivity analyzers, and electric conductivity meters are made use of to do these tests accurately.

Chemical testing strategies are made use of to establish the chemical structure and pureness of materials. Techniques such as mass, chromatography, like this and spectroscopy spectrometry are frequently utilized, along with customized tools made for these objectives.

Applications of Materials Examination Results

The results of products testing offer beneficial understandings right into the efficiency and viability of various products for certain applications in different here markets - materials test lab. These examination results play a critical function in establishing the top quality, durability, and safety of products made use of in making proceduresOne of the essential applications of materials examination results remains in the area of building. Designers and designers count on these outcomes to select appropriate products for developing structures, such as bridges, skyscrapers, and residential buildings. By performing tests on products like hardwood, concrete, and steel, they can make sure that these materials meet the called for standards and can withstand numerous environmental conditions.

In the aerospace sector, materials examination results are important in determining the suitability of products for aircraft parts. By subjecting products to rigorous screening, engineers can examine their mechanical buildings, resistance to warm and rust, and ability to hold up against high-stress conditions. This details is important in guaranteeing the safety and security and reliability of airplane.

Future Patterns in Materials Testing

In the world of materials screening, developments in products evaluating techniques are shaping the trajectory of the area, ushering in a brand-new era of advancement and accuracy. As technology remains to evolve, so does the requirement for advanced screening techniques and devices. One future fad in materials testing is the combination of expert system (AI) and equipment understanding algorithms right into testing processes. These modern technologies have the potential to improve the efficiency and accuracy of examination results by analyzing big amounts of information and recognizing patterns that may not be quickly obvious by human beings. Additionally, the use of non-destructive screening approaches is becoming increasingly prominent. These methods enable the evaluation of product properties without triggering damages or change to the example, making them ideal for evaluating irreplaceable or beneficial products. There is a growing focus on sustainability in materials testing. This consists of the growth of screening approaches that reduce waste and power intake, along with making use of environmentally-friendly products in have a peek at this site screening devices. On the whole, the future of products screening is defined by constant development and a commitment to improving precision, sustainability, and effectiveness.Verdict

Finally, materials testing plays an important role in different industries by ensuring the high quality, safety, and efficiency of products utilized in products and structures. It entails evaluating a vast array of products using various strategies and equipment to review their mechanical, physical, and chemical residential properties. The results acquired from products testing are utilized to make enlightened decisions in material production, option, and design processes. As innovation breakthroughs, materials evaluating laboratories will certainly remain to adjust and improve their approaches to fulfill the advancing requirements of markets.With a combination of sophisticated techniques and specialized equipment, materials examination labs are able to assess the properties of steels, polymers, compounds, and other materials under various problems and stress factors. By carrying out tests on materials like concrete, timber, and steel, they can make certain that these products satisfy the required standards and can hold up against numerous environmental conditions.

In the aerospace industry, products examination results are essential in determining the viability of materials for aircraft elements. By evaluating materials for their stamina, resistance, and flexibility to effect, manufacturers can pick the most ideal materials for various automobile parts, such as body panels, engine parts, and safety and security functions.In the world of materials screening, developments in products evaluating approaches are forming the trajectory of the field, ushering in a brand-new era of advancement and precision.

Report this wiki page